Calibration tools are vital for collision centers, enabling precise repairs and ensuring vehicle safety. Integrating these with digital estimating systems is critical, as shops transition from manual to data-driven practices. Seamless integration avoids a "calibration tools collision," enhancing productivity, accuracy, and turnaround times. Best practices include thorough testing, compatibility checks, clear data transfer protocols, and mimicking auto detailing workflows for transparent, competitive pricing in the automotive industry.

In today’s digital era, construction projects rely heavily on accurate estimating and precision measurement. The integration of calibration tools with digital estimating systems offers a promising path to enhanced efficiency and reduced errors. However, the collision between these distinct worlds presents unique challenges. This article delves into understanding the crucial role of calibration tools in precise estimating, explores the obstacles that arise when physical tools meet digital systems, and provides best practices for seamless integration. By addressing the topic of calibration tools collision, we aim to equip professionals with insights for effective system combination.

- Understanding Calibration Tools and Their Role in Precision Estimating

- The Challenges of Collision: When Digital Systems Meet Physical Calibration Tools

- Seamless Integration: Best Practices for Combining Calibration and Digital Estimating Systems

Understanding Calibration Tools and Their Role in Precision Estimating

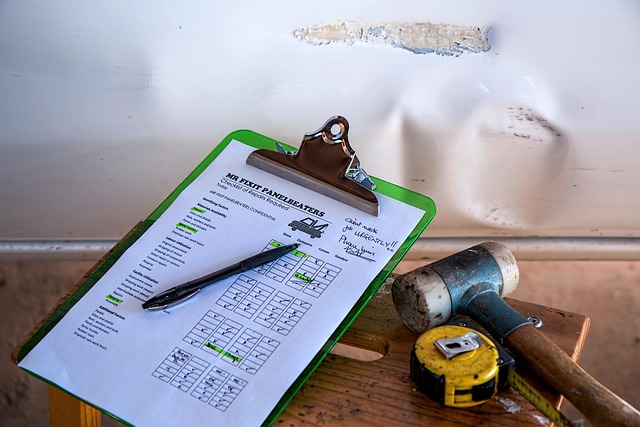

Calibration tools play a pivotal role in achieving precise estimating within digital systems, especially in the automotive industry. These tools are meticulously designed to ensure accuracy and consistency in measuring and adjusting various components of a vehicle, such as suspension, steering, and brake systems. By collision center standards, they help in identifying minute deviations that could impact safety and performance, making them indispensable for auto collision centers aiming for flawless repairs.

In the context of auto collision repair, calibration tools act as guardians of quality control. They enable technicians to fine-tune and calibrate machines used in estimating damage, ensuring that every repair is accurately assessed. This precision is crucial for restoring vehicles to their pre-collision condition, fostering customer satisfaction, and maintaining the integrity of the auto collision center’s reputation.

The Challenges of Collision: When Digital Systems Meet Physical Calibration Tools

In the realm of modern auto body repair, where digital estimating systems have become the norm, one significant challenge emerges when integrating them with physical calibration tools. As auto body shops strive to transition from manual, time-consuming methods to efficient, data-driven practices, the harmony between these two essential components is paramount. Digital estimating requires precise input and calculations based on accurate measurements, but these are often provided by traditional calibration tools used in collision repair.

The complexities arise when these physical tools, crucial for ensuring exacting repairs, especially in intricate auto frame repair scenarios, might not always align with the digital system’s expectations. Vehicle body shops face the task of bridging this gap to deliver seamless auto body services. This integration is a delicate process that demands meticulous attention to detail to maintain the accuracy and reliability associated with high-quality collision repair work.

Seamless Integration: Best Practices for Combining Calibration and Digital Estimating Systems

The seamless integration of calibration tools with digital estimating systems is paramount in modern automotive workshops and body shops. Best practices involve ensuring compatibility between software and hardware to avoid any issues related to a calibration tools collision. This begins with thorough testing to verify that all components work harmoniously together, mimicking the workflow of an auto detailing or vehicle body repair process as closely as possible.

Workshops should establish clear protocols for data transfer and synchronization between calibration tools and digital estimators, particularly when dealing with complex auto body restoration tasks. Efficient communication ensures precise measurements are accurately fed into estimating systems, leading to more accurate quotes and faster turnaround times. By embracing these practices, shops can enhance productivity while providing customers with transparent, competitive pricing in the competitive automotive industry.

The integration of calibration tools and digital estimating systems offers a powerful synergy, enhancing precision and efficiency in various industries. By seamlessly combining physical calibration tools with advanced digital technologies, organizations can overcome challenges related to collision and achieve accurate, reliable estimates. Adopting best practices for this integration ensures that both the physical and digital elements work in harmony, providing a robust framework for improved decision-making and competitiveness in today’s market.